Safety nets are often used as a passive protection device to prevent fall from height injuries. However one must think about the ideal and non ideal conditions while using Safety Nets. Construction sector/ industry is most vulnerable with respect to Work at Height Falls. Many researches have evaluated the effectiveness of Safety Nets . Many reasons lead to poor effectiveness of Safety nets in field. Some reasons are as below:

1- Preexisting damage in the Safety nets i.e due to storage, transportation and handling issues.

2- Damage due to sharp edge material fall on the Safety nets.

3- Poor installation practice.i.e Too much tension or too much Sag.

4- Type of Safety net material.

5- Repeated loading on the Safety nets at same point/ position.

6- Hidden defects in the Safety nets.

7- Ageing of Safety nets.

8- In use damage like Use adjacent to Hot objects, use in sunlight or in water.i.e Both lead to degradation of polymer (Safety net).

9- Poor repair and replacement practices.

So how one can identify whether Safety net is fit for use or not?

Please find below few basic tips to identify fitness of Safety nets and maintain its effectiveness:

1- Purchase Safety nets from reputed supplier and of certified standard. CE etc.

2- Store them as per manufacturer recommendations.i.e away from sunlight and prevent water exposure, store away from hot objects (this may lead to melting of polymer) etc.

3- Pre-use inspection regime should be developed . Aimed to identify the preexisting damage in the Safety nets.

4- Prevent Safety nets from sharp edges.

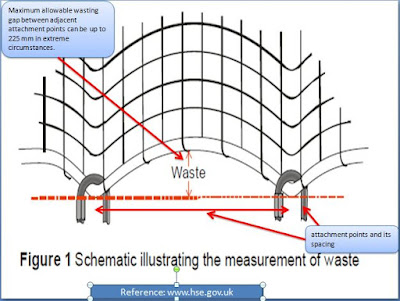

5- Attachment spacing should be standardized and should be kept small as much possible to prevent loading on attachment point.

6- Special attention should be paid to peak loads which are generally found adjacent to the drop point.

7- Maximum damage happens often at attachment points so special care should be taken while in use.

8- Repeated loading reduces Safety nets elasticity so they should be replaced if received any dynamic loading.

9- Safety nets should be provided with proper tension so as to keep drop load within the Safety net after fall. Also too much sag lead to displacement of the safety nets and should be avoided.

10- Drop points should be made free from defects in the Safety Nets.

11- In case of multiple meshes damage then replace it with new patch of material complying EN1263-1.

12- Never use makeshift arrangements to repair damage safety net.i.e Prohibit use of threads, cable ties.

Reference: www.hse.gov.uk

If you like the blog then please like and post your comment. Include suggestions for improvement if any.

Amazing article! i have bookmarked this article page as i received good information from this. All the best for the upcoming articles. I will be waiting for you new articles. Thank you! kindly visit us.

ReplyDeleteTarpaulin Suppliers In India